Blog Post #5: Finishing the Design of My Second Robot

As I was designing my second robot, one problem became immediately apparent: weight. With the original thicknesses of steel, carbon fiber, and walls in my TPU armor that I thought I could use, I would end up being way over the 1lb weight limit.

In order to track the weights of my parts, I started to use a spreadsheet. A set of my parts had a fixed weight I could not change even if I wanted to: motors, screws, other electronics, etc. I weighed all of them in order to figure out what my budget was. I also needed a way to estimate the weight of my metal and carbon fiber parts as those would weigh the most and I would have very few good ways to change them once I had them. To estimate their weights, I used a feature in Autodesk Inventor where I could input the material and get a part's weight out. I was unable to use this previously as the density of printed parts is not constant so for those, I would use my 3D printer's slicer to get a rough guess as to how much material would be used during the print.

|

| My weight-tracking spreadsheet for both robots |

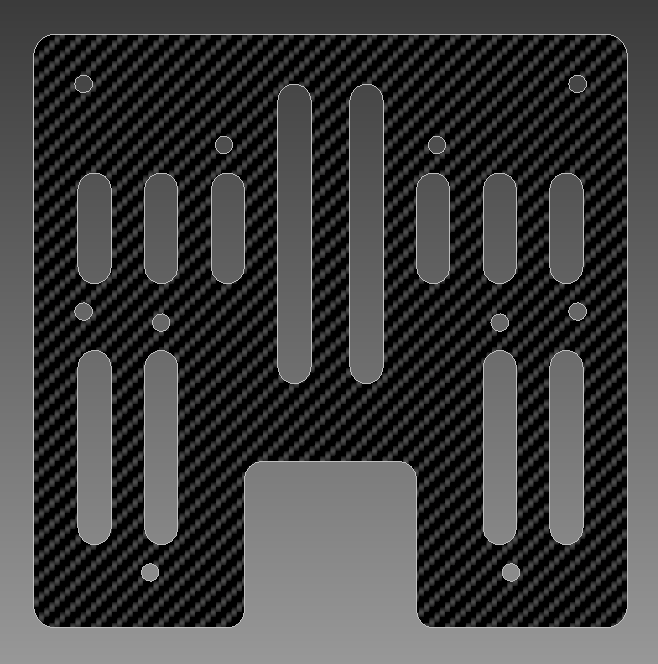

The original thickness of carbon fiber that I was going to use was 1/8", but I quickly realized that that was going to use too much of my remaining weight. Instead, I chose to go down to 1/16" plates which would hopefully also be easier to CNC. Also to save weight in my plates, I added a large number of slots that would lessen the amount of material but were small enough that stuff would stay inside of the robot.

|

| Top cover |

Throughout my robot, there were going to be a number of parts that would need to be rigid but were complicated enough that I would need to 3d print them. These parts included the holders for my drive motors and the place where I would attach my power switch. Because weight was a concern for me, I needed to use the lightest filament I had at my disposal. This ended up, surprisingly being carbon fiber infused PLA. While this filament sounds like a good idea to have used earlier on, plastic with additives is not allowed in the plastic class, and on top of it, the filament is more rigid but not really stronger than regular PLA. It does have a nice visual appearance and texture though and the red that I used looks really good so there is that.

|

| Red PLA Cf |

Another way that I managed to cut weight was by reducing the number and length of screws in my design. One of the surprising benefits of making my carbon fiber plates thinner was that it allowed me to swap all of my 10mm screws to 8mm screws. I was also able to creatively reduce my screw count in one location. Both my weapon mounts and the side armor of my robot needed attachment points at the front of my chassis. What I had originally was the side armor wrapped around a 24 mm standoff while my weapon mounts had an 18mm standoff sandwiched between the top and bottom keeping them securely attached. What I did was make it such that the side armor wrapped around that 18mm standoff which saved me the weight of two standoffs and four screws.

|

| The side armor is highlighted in blue |

Comments

Post a Comment